HOW IT'S DONE: DESIGN, PROTOTYPING AND MANUFACURING OF MBA PRODUCTS

DESIGN: Every MBA product starts with an idea. Sometimes that idea is for a brand new theme of products; sometimes it may be an addition to an existing series. Ideas come from our observations of which games are being played, which rule sets and figures are popular and certainly from suggestions from customers.

Some ideas spring form fully formed and others are vague and incomplete. We gather them all. We have a master list of product ideas that runs more than a dozen pages. Most of these will never come to anything, but nothing is discarded. Some of these partial ideas find themselves joined together into a product that serves several purposes.

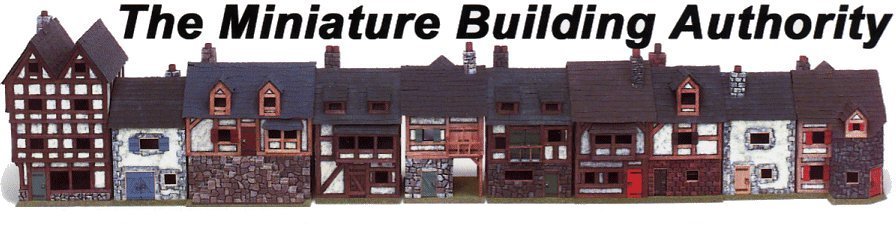

MBA buildings are rarely intended as models of specific historical prototypes. This can be very limiting in the usefulness of that piece, and therefore hampers sales potential. Our purpose is to provide a "historically plausible" building that could be used in many gaming situations. For example, the "Eurovillage Series" buildings could be used for most any game in northern Europe in the past thousand years, plus most fantasy scenarios.

This does not mean great care isn't taken with research. We have collected a fair library of reference and photo books covering areas of interest. The public library and the Internet also supply valuable information. And friends and customers continually send us images.

This gets distilled into an archetypal image. Our best success comes from creating a building that matches an unconscious vision shared by our customers. When you see our "Halfling House", no explanation is required. You know what it was instinctively. The more closely our design matches our cultural expectation, the more readily accepted that piece. The "Old Mill" and the "Town Wall Series" are good examples.

The reality of gaming requirements will often modify a design. 15mm players wish to place stands of troops inside, so the building must be large enough to allow the most common sizes. Having a removable roof can effect how a model breaks down. Windows, stairs, and interior details can all influence final design

PROTOTYPE: Depending on the complexity of the design, a full, detailed drawing may be created before any fabrication of a prototype. Drawings are done by hand, using a drafting table, t-square and pencils. To date, only one MBA building was designed on a computer, and that with the assistance of my son, Ian.

Because the final production pieces will cast from molds taken from my prototypes, it is crucial that the prototype be exactly what we want. Wall thickness and fit must be exact.

Most MBA building prototypes are constructed of polyurethane foam called "Sign Foam". This resembles the green florist foam used for dried flower arrangements but heavier, about the density of balsa wood. Purchased in a 48"x96"x1" sheet for several hundred dollars, the first step is to cut this into smaller sheets. These sheets are then sliced into thinner sheets. 1/8th inch to ¼ inch are most common. All this work is done on large woodworking power tools.

With appropriate material now at hand, the design is broken down and cut out of foam. Again power tools are the only precise method. I use a full size table saw, a miniature table saw, a jigsaw, a band saw, a drill press and a bench top belt sander to shape model components. Medium viscosity cyanoacrylate is the adhesive of choice for assembly. If the building is to have a stone or masonry surface, moto-tools are used with a variety of bits to engrave that detail. Yes, it can be boring.

With surface details completed, the model is glued to a base, usually Medium Density Fiberboard. Roofs are built from plywood, then covered with either textured styrene sheet (Evergreen or Plastruct) or other appropriate material. "Eurovillage" buildings have shingles that are cut from card stock and installed one row at a time. This is a very tedious job for suitable for apprentices.

Other details are added at this point. Bits of jewelry, wire, styrene, sculpting putty and wood are most frequently used. With five decades of modeling experience, I am confident of fabricating any details required.

Painting usually occurs after all details are added. Since the production pieces will be painted this way, it seems only fair that I also do this. Commonly, I prime the building with flat black enamel from a spray can, just as if it was a figure. The enamel will stick well to all the variety of materials used and show up any final blemishes that need to be addressed.

Prototypes are painted by hand, using water-based hobby paints from the craft store. Dry brushing and washes are used to add subtlety to the finish. Final examination is by several pairs of eyes and includes a few days sitting atop my television just to make sure that all is perfect.

PRODUCT SELECTION: The process of design and prototyping goes on year round. We continually update and discuss which designs should be included in the next production batch. We must balance factors such as reinforcing our popular series, adding a whole new series, replacement of aging designs, and restocking popular pieces. This often leads to spirited squabbles. Everyone has a favorite idea. In the end, about 15-20 pieces are boxed up and handed to our manufacturing contact.

PRODUCTION: We have been fortunate that although our manufacturing is done in China, we do all our business through an "agent" here in Atlanta. We deliver the prototypes to them; they ship them overseas to an agent in China who negotiates with the local factory owner. They bid a price, we moan and wail.

We offer a lower price, they tear their hair and mutter. After several weeks, an agreement is reached. On very few occasions we have dropped a product when pricing could not be agreed.

A "production prototype" is produced from our prototype, painted and returned for our approval. Small quality issues are addressed then. Our boxes feature photos of our product and these are taken at this stage, artwork details confirmed and production runs finalized. Most MBA products are produced in the hundreds at a time. We intend this to be sufficient for a year or two of sales, but are sometimes taken by surprise by customer demand. Recent success with "Limited Edition" items may lead us toward smaller runs of more unusual ideas. In truth, almost any MBA product should be considered a "Limited Edition".

Then we wait. Murphy's Law does rear its head occasionally, but things usually move smoothly, if sometimes slowly. Finally we receive word that all is done and will ship shortly. Then there is a voyage on a genuine "slow boat from China", arrival in California (where we once faced a longshoreman's strike), clearing US Customs, and a truck trip to sunny Tampa. We are kept abreast of each of these stages, but have no control over events. Our long time customers know that we share their frustrations over delays. Finally the truck drops off a 20-40 foot shipping container at our warehouse, where it will be unloaded on the hottest day of the year. A few hours to sort things out, and the first orders get shipped out that day.

The time from delivery of prototypes to arrival of the shipping container is 6-10 months. We start this process earlier each year, but the Chinese calendar seems to lose a month somehow.

We have recently added a domestic casters to our manufacturing sources. Prototyping is the same, but local access allows for smaller, more timely production runs of items that are not viable through the overseas path. These products can be found in the "MBA Direct" section.